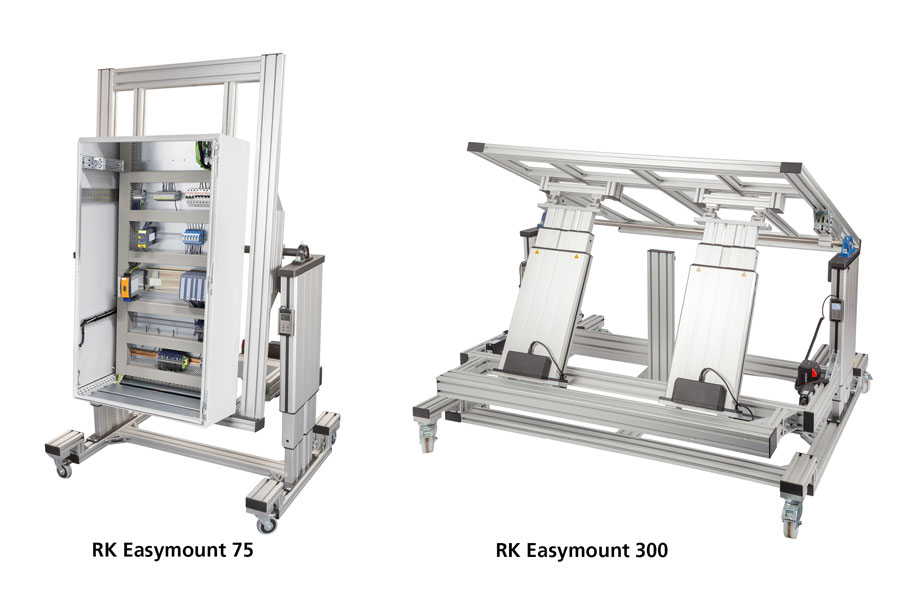

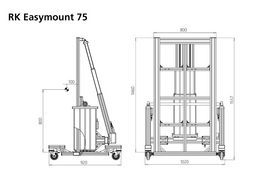

Mobile and ergonomic workstation solutions for control cabinet construction/control cabinet assembly

Optimise your working procedures and increase efficiency in control cabinet construction with our control cabinet assembly table. Our control cabinet assembly tables are characterised by their stable construction, ergonomic design and high functionality. It provides you with a convenient work surface on which you have all the required tools and materials on hand. Thanks to the individually adjustable height and tilt position of the table, you can take up an ergonomic working position and thus reduce physical strain. With our control cabinet assembly table, you can not only save time and costs, but also improve the quality of work. Increase the efficiency of your assembly processes and maximise your productivity with our individually adaptable workstation solutions.

- Benefits of our ergonomic assembly tables:

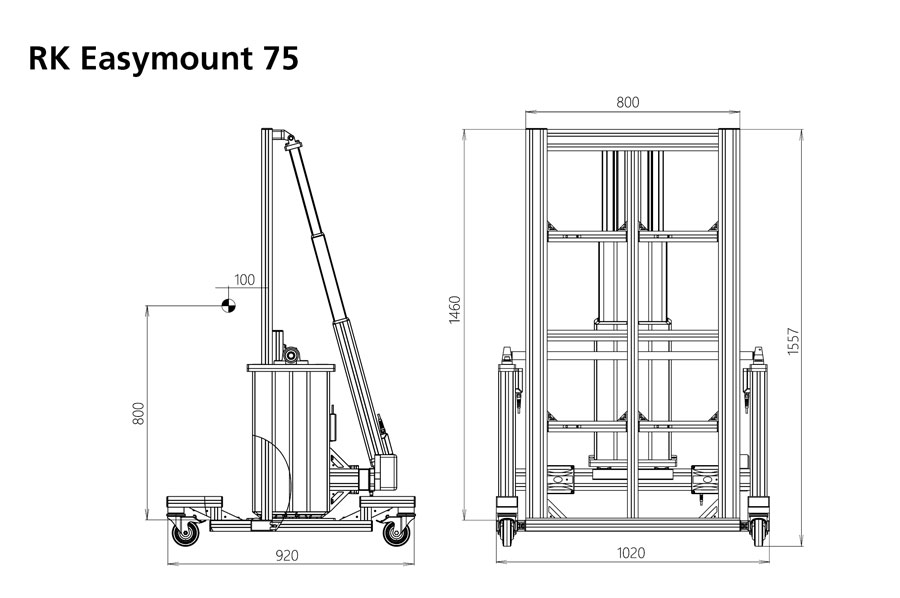

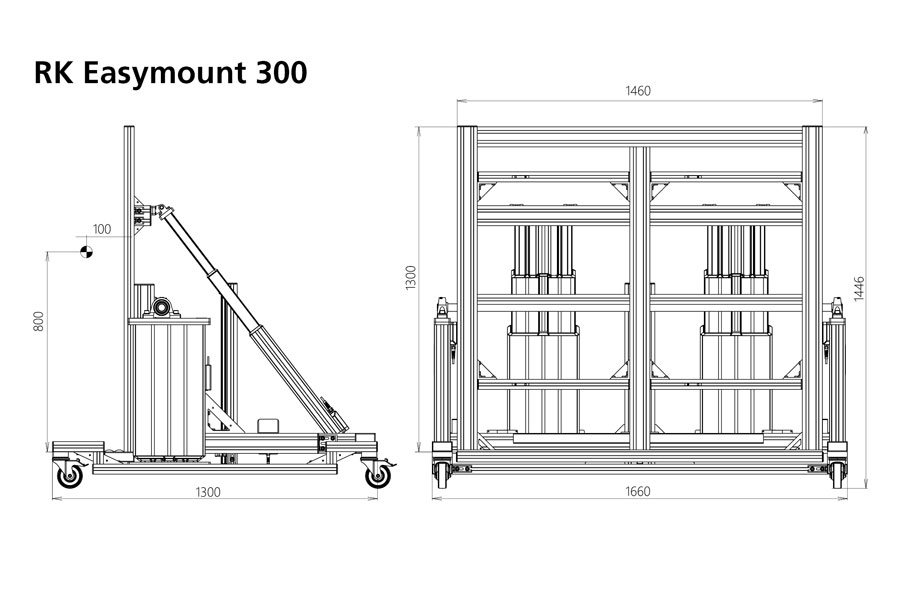

- Ergonomic – Work surface with adjustable height and tilt position (0-90°) for convenient working position which provides physical relief

- Increase in productivity – Optimisation of working procedures and reduction of downtimes thanks to ergonomic working

- Flexibility – Mobile thanks to castors and cordless battery-operated control, ideal for use in different locations

- Robust – Stable and resilient, suitable for loads of up to 3000 N (design for higher loads available on request)

- Adaptable – Individually adjustable for specific customer requirements, supports tailor-made work processes

- Compatible – Use of commercially available rechargeable battery systems, no special energy supplies required

- Service – Technical consultation locally, workshops/training courses, repair service/spare parts

Individual assembly tables for control cabinet construction, assembly of bulky components, and much more

We provide you with individually adapted assembly equipment which optimally support your work processes. Ergonomic and adapted working also makes for more mobility and fewer downtimes for the employee. The areas of application are control cabinet assembly | control cabinet wiring | control cabinet construction where employees can carry out wiring and programming tasks, working with low fatigue for longer periods.

Modern assembly workstations provide a wide range of options

Modern production processes require flexibly and ergonomically adjustable workstations and conveying solutions. Modern production places high demands on the flexibility, safety and ergonomics of stationary and mobile workstations, and also conveying solutions. They must guarantee that employees are relieved of physically strenuous or non-ergonomic tasks, and that the working procedures – for example, after a shift change – can be implemented reliably and flawlessly.

This applies in particular to mobile workstations which are used at multiple locations for changing tasks, and for material or workshop trolleys. In the process, there are no limits to the adjustment options: nowadays, thanks to lifting columns and electrical cylinders, the working height, tilt position and even reach settings – to name but a few – can be adapted to the respective employee. The cost-efficiency of these workstations is also an important aspect: using modern controls, for example, after a change of worker, the workbenches can be reset quickly – retooling times or even separate workbenches for other process steps can thus be minimised.

Battery-operated synchronous controller for mobile applications

In the past, when implementing mobile, adjustable workbenches and conveying solutions, the often very long energy supply cables used to prove disruptive. They are not only a considerable stumbling hazard, but can also cause considerable hazards for personnel and the machine (electric shock) in the event of damage to the cables (for example as a result of being run over by trolleys). Therefore, when it comes to systems with cables, the voltage supply has to be interrupted for safety reasons for travelling from point A to point B. In the process, neither the height nor the tilt position can be adjusted. This is very cumbersome for operators, and is time-consuming. The MultiControl II duo accu is the solution. This synchronous controller has been specifically developed for cordless moving of lifting columns and electrical cylinders. And the cherry on the top: the new control's specially designed battery adapter for standardised lithium-ion rechargeable batteries from well-known manufacturers. Users can thus, in the ideal case, use existing 28 V rechargeable batteries for the energy supply to the control and the connected drives. As a result, the system functions independently of the stationary, wired voltage supply, thus making new areas of application possible.

Find out more about the MultiControl II accu MultiControl II accu videoImmer der richtige Kontakt

Ihr Ansprechpartner bei RK ROSE+KRIEGER: